The key to the art of making fine miso lies in the process of fermentation, a process which, throughout its long and varied history around the world, has served three fundamental purposes: the improvement of a food’s digestibility; the transformation of its flavor and aroma, color and texture; and its preservation without refrigeration. Watching the drama enlarged a thousand-fold and presented in time-lapse color photography, one witnesses a near-miraculous world in which tiny spores burst into blossom like elegant and complex flowers, enzymes reach out inquisitively like long fingers melting solid particles at their touch, and populations of mold explode until they have totally enveloped the foods – or “substrates” – which support their life.

– The Book of Miso, page 28

Miso is made through a unique double fermentation process. The first stage of fermentation involves making koji, or cultured grain. The second stage begins when the matured koji is mixed with the cooked beans and other ingredients.

Growing rice at South River Farm, Summer 2023

We incorporate a small amount of home-grown rice into each batch of rice miso.

Organic grain, organic bean, sea salt: the primary ingredients of miso making at South River

Grain that has been soaked overnight is placed in a netted muslin sack and steamed in our wood-fired cauldron for about 45 minutes. We make koji using either brown rice or barley, depending upon the variety of miso.

Soaking kettles and cooking cauldron (embedded in masonry stove)

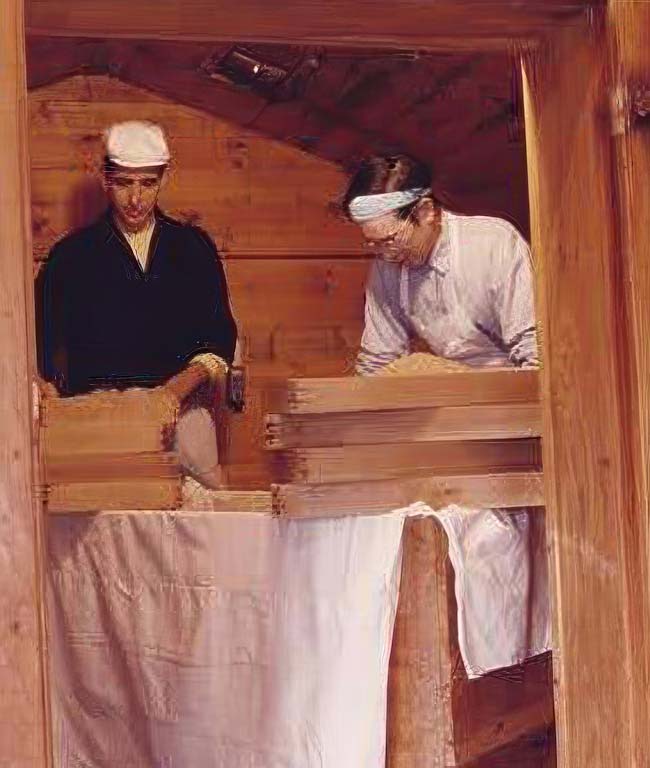

Unloading steamed grain from the cauldron.

STAGE I –MAKING KOJIDay 1 – steaming and inoculating the grainThe steamed grain is spread out on cooling tables, and cooled down to a temperature of 112 F, before it is inoculated with the spores of Aspergillus oryzae, a beneficial mold that will transform the grain into sweet, fragrant koji over a two-day period.

All line drawings are from The Book of Miso,

by William Shurtleff and Akiko Aoyagi;

(Berkeley: Ten Speed Press, 1983)

All line drawings are from The Book of Miso,

by William Shurtleff and Akiko Aoyagi;

(Berkeley: Ten Speed Press, 1983)

The koji is then transferred to a large wooden box on wheels, which is called the ‘crib’, and moved into a small incubation chamber called the koji room. The koji will stay in the crib overnight, and will begin the first stage of fermentation in a carefully controlled environment, where the temperature of the koji is closely monitored and recorded. As the mold starts to metabolize the grain, the temperature of the koji rises overnight from about 82 to about 100 F.

The door to the koji room

The crib, in the koji room

Koji trays stacked in koji room in their first formation.Day 2 – koji incubation

Koji trays stacked in koji room in their first formation.Day 2 – koji incubationLater in the day each tray of koji is stirred by hand, to further disperse the heat generated by the intense metabolic growth of the Aspergillus mold. The trays are restacked in a more open formation, to allow more oxygen to nourish the koji, and to prevent overheating. The warmth given off by the koji is now sufficient to maintain the necessary heat level in the koji room itself.

Koji trays are re-stacked into their second formation.

On Day 3 the koji is ready to be harvested. By this time, about 48 hours after it was initially steamed and inoculated, the grain is covered with a fragrant bloom of the beneficial white mold. During its growth, this Aspergillus mold has transformed starches into complex sugars and created a vast storehouse of digestive enzymes, which are crucial to the second stage of the miso fermentation process.

Barley koji on day 2 Barley koji on day 3

Note the white mold growth covering the barley koji in the trays at harvest time on day 3.

Harvest time

Day 3 – harvesting the koji

The harvested koji is mixed with a measured amount of sea salt. The amount of salt used depends on the variety of miso and its intended length of fermentation. The salt preserves the enzymes and nutritional value of the koji, while preventing any further mold growth. The salted koji is set aside until needed for mixing with the cooked beans in Stage 2.

Beans are first sorted, then washed and soaked, in preparation for cooking the following day. At South River Miso, we use different beans for different varieties of miso, including yellow soybeans, black soybeans, azuki beans, and chickpeas.

After soaking overnight, the beans are boiled by gentle wood fire for about six hours of active cooking in the cauldron of our massive masonry stove. They remain in the cauldron overnight, cooking altogether for about 20 hours. This long, slow cooking of the beans by gentle wood fire is the open secret of traditional miso making.

The next morning the cooked beans are transferred into a large, stainless steel treading box and allowed to cool down to body temperature.

‘Seed’ miso from a previously produced batch of the same variety of miso is added. As in sourdough bread making, a lineage of culture is passed on from one batch of miso to the next, from the dawn of miso making to the present time.

Seed miso is first diluted in bean juice from the bean cooking. This mixture is then poured over the beans in the mixing box.

The beans are mashed underfoot. Until World War II, nearly all miso was produced in this way. At South River, the miso maker wears two pairs of organic cotton socks as well as plastic foot coverings. The result is miso with the traditional chunky texture, called 'tsubu' miso in Japanese, the oldest form of miso.

The salted koji (from Stage 1) is now mixed with the mashed beans. For our specialty varieties, additional ingredients are incorporated at this time as well (such as wild leeks and dandelion greens for the Dandelion Leek Miso).

The foot treading is another sacred moment in the miso making process at South River. The grain koji, the cooked beans, and the seed miso are mixed together for the first time and the human being becomes fully integrated with the miso making craft. He or she becomes a miso maker in body, soul, and spirit.

The treading process can be a deeply meditative experience.

When the treading process is complete, the raw miso is ready to be removed to the vat building and placed into the designated fermentation vat.

Once the vat is full, the miso is packed down, smoothed off, and sealed with a muslin cloth and wooden pressing lid with heavy weights placed upon it. Liquid rises up to the surface and seals the miso from exposure to the air. The second stage, anaerobic fermentation, begins.

Smoothing down the miso in the vat

Covering miso with muslin cloth

Placing the pressing lid on top of the muslin cloth

Placing heavy blocks on top of pressing lid

The raw miso will remain in the vat until it is ready for harvest. This may be for as long as three years (our hearty varieties) or for as few as three weeks (Sweet White miso).

Our wooden vats are made of American cypress. We use only wooden vats only for our miso fermentation. The smaller vats have the capacity of about 2400 lbs. of miso, and take one week to fill. The large vats have three times this capacity. They can hold over three tons of miso and take three weeks to fill.

Our work is done for now. Inside the vats, hidden from view, the transformation begins, and miso slowly but surely becomes what it is to become. Unhurried aging blessed through the cycles of time is one of our secret ingredients, bringing forth the finest of flavors.

Time is a flowering field,

Maternal Nature a mighty living being.

Everything is fruit; everything is seed.

When the designated time has elapsed and the fermentation process has come to fruition, the vat is opened and the miso is harvested by hand.

During the cooler months, we ship anywhere in the United States. The rest of the year, please visit your local grocer.

PH: 413.369.4057

Information

Sign up for our newsletter, South River Currents, where we share stories, photos, recipes, videos, and more.